Reduce waste, reclaim time and boost your bottom line

Streamline everything from Work-Orders to Maintenance Records

so your team always have what they need, when they need it.

Streamline everything from Work-Orders to Maintenance Records so your team always have what they need, when they need it.

Seamlessly Coordinate your Departments

Build your own custom Enterprise Resource Planning (ERP) system to visualise your operations, cut overheads and unify every department across your factory.

Research & Development

Coordinate R&D projects and track progress from concept to prototype

Engineering & Design

Manage Engineering Change Orders (ECOs) and run controlled Design Reviews

Supply Chain Management

Gain clarity on inventory, suppliers and lead times

Production Management

Plan, schedule & manage your Bills-of-Materials (BOMs) and Work Orders

LEAN Manufacturing

Embed LEAN principles to reduce waste and improve process flows

Quality Management

Create a tailored Quality Management System (QMS) with audit trails

Maintenance Management

Log maintenance issues, schedule repairs and maximise your OEE

Sales & Marketing

Manage your sales pipeline, marketing campaigns and customer relationships

Human Resources

Manage training records, timesheets and development plans

Health, Safety & Environment

Record near misses, manage environmental compliance and monitor risk exposure

Research & Development

Coordinate R&D projects and track progress from concept to prototype

Engineering & Design

Manage Engineering Change Orders (ECOs) and run controlled Design Reviews

Supply Chain Management

Gain clarity on inventory, suppliers and lead times

Production Management

Plan, schedule & manage your Bills-of-Materials (BOMs) and Work Orders

LEAN Manufacturing

Embed LEAN principles to reduce waste and improve process flows

Quality Management

Create a tailored Quality Management System (QMS) with audit trails

Maintenance Management

Log maintenance issues, schedule repairs and maximise your OEE

Sales & Marketing

Manage your sales pipeline, marketing campaigns and customer relationships

Human Resources

Manage training records, timesheets and development plans

Health, Safety & Environment

Record near misses, manage environmental compliance and monitor risk exposure

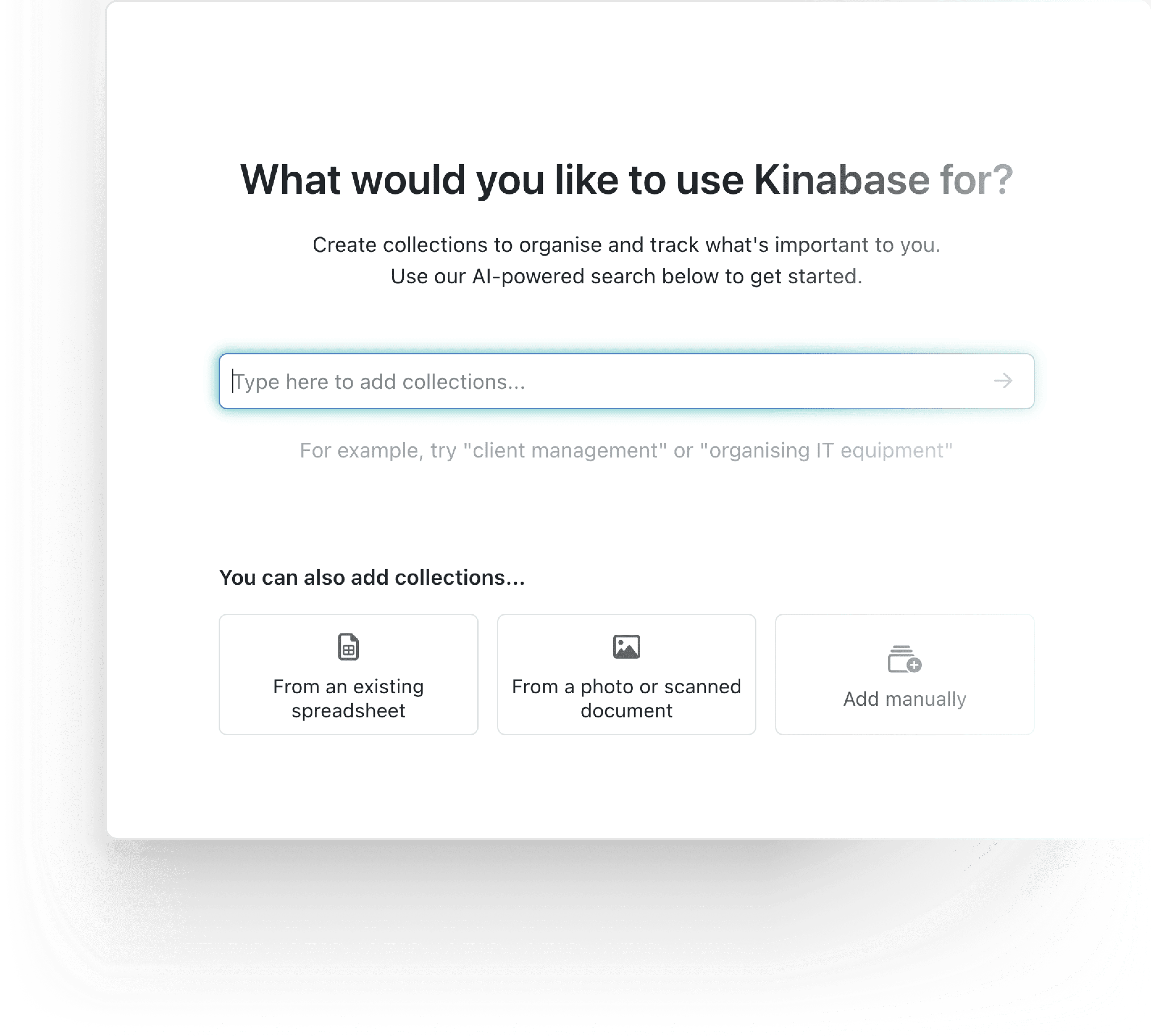

Digital Transformation has never been more accessible

Streamline Spreadsheets into smart Workflows

Convert scattered spreadsheets into structured processes so your team works faster and smarter. Protect your operations with an integrated system, ensuring everyone works from the same data.

Replace chaos with clear, logical workflows and shared visibility.

Spreadsheets isolate

For complex manufacturing, spreadsheets fall short

Kinabase connects

End the confusion with a shared source of truth

One platform. One project. Zero confusion.

Documents at your fingertips

Controlled Processes

Instant context

Automated notifications

Collaborate effectively

Continuous Improvement

Achieve Operational Clarity

Use Kinabase to bring all your operational data into one shared platform so everyone works from the same information.

Ensure materials flow seamlessly and production stays on track

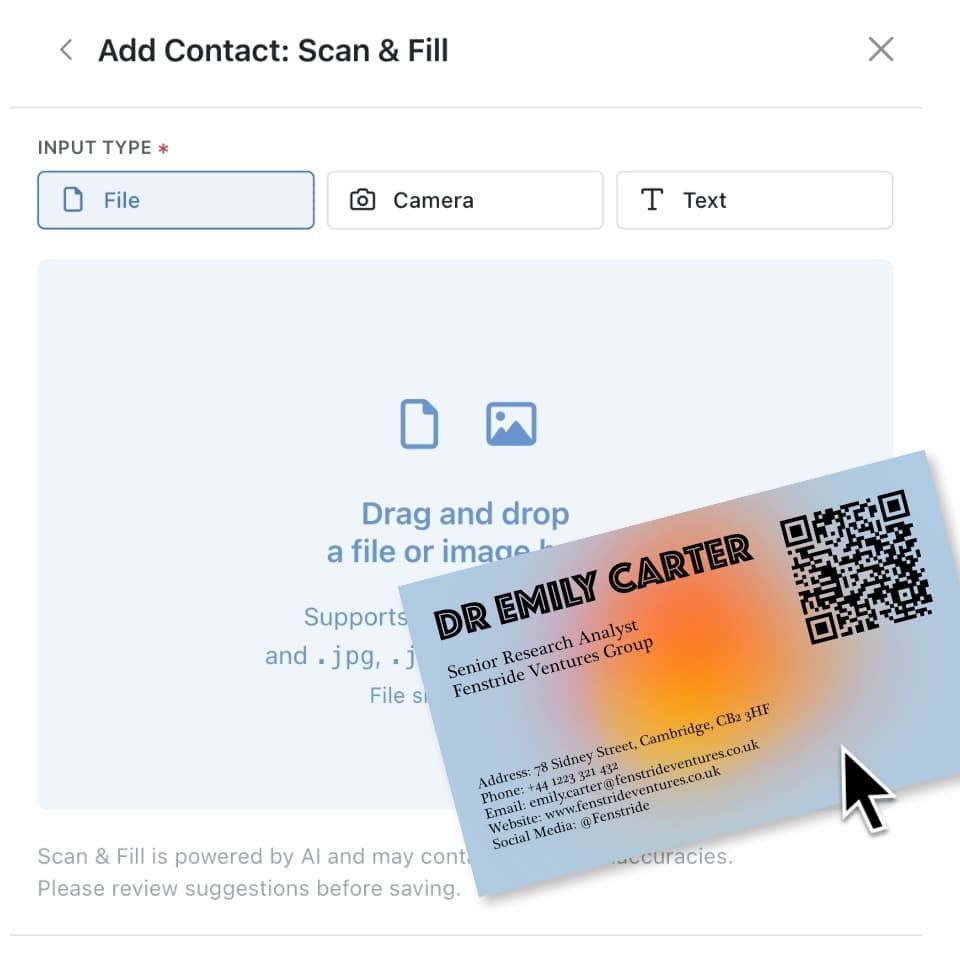

Save time & resources with state-of-the-art technology

No more manual data entry

Scan delivery notes, business cards, images or upload spreadsheets to automatically populate records in seconds.

Effortless record and label printing

Print records and labels directly from Kinabase, so that you can always find what you need.

Automate administrative tasks

Easily build custom automations to eliminate repetitive work and free your team to focus on value-adding activities.

Optimise stock levels with intelligent QR code tracking

Keep your production line performing at its peak

Log maintenance issues, schedule repairs and track your Overall Equipment Effectiveness (OEE), to maximise uptime and maintain consistent production performance.

5S Check System

Maintain organised, efficient workspaces.

Total Productive Maintenance Plan (TPM)

Prevent downtime before it happens.

Overall Equipment Effectiveness (OEE)

Measure, monitor and improve performance.

Industry 4.0

Harness technology to connect, analyse and optimise.

Unlock measurable time savings with Kinabase

From data entry, to data analysis, Kinabase streamlines every process to deliver clear quantifiable results for Manufacturing teams.

* Based on annonymised usage data from 100+ Kinabase customers between Jan 2024 - Mar 2025

See Kinabase in action

How MTRL Streamlined Custom Furniture Design with Kinabase

"We'd absolutely recommend Kinabase to others wanting to improve their business processes. You may think your processes are too unique for any one system to handle, or it will take too much time to explain the intricacies of your business, but in a few short days you could adapt Kinabase to your system and needs, and it would perfectly capture your data the way you want to portray it."""

Nicolas Miller

Operations Manager at MTRL